2018, Abdali, M.

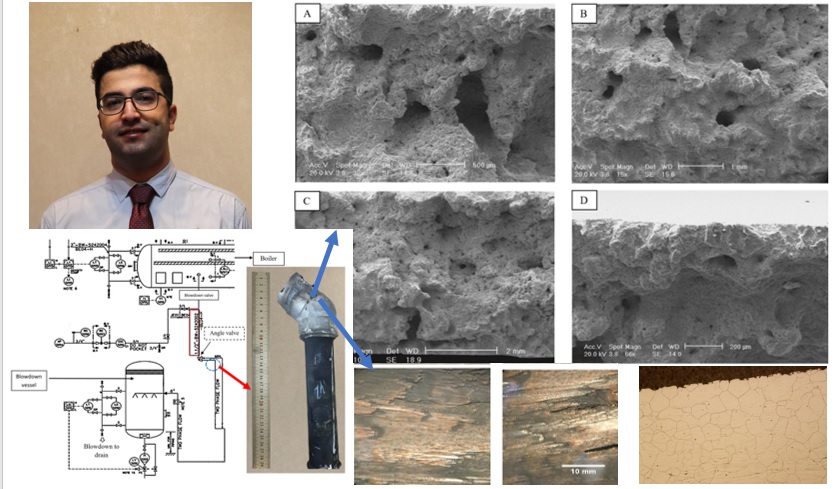

THESIS (BSc, 2016-2018): Metallurgical Aspects of a Blowdown Pipe Failure in a Petrochemical Plant

This study investigates the premature failure of AISI 304 stainless steel pipe in a blowdown unit, used between boiler and blowdown vessel in a petrochemical plant. First leak was reported in the elbow after few weeks of service. The leak was repaired. The repaired unit showed a crack in the pipe in the vicinity of the elbow only after less than 6 month of service at 150 ºC. Failed pipe and elbow were taken out of the system, in order to conduct a failure analysis. Visual inspection, optical and electron microscopy, electron dispersive spectroscopy (EDS) analysis and hardness measurements were employed to identify failure cause. Results showed high concentration of oxygen within the grain boundaries of failed 304 stainless steel. This was the locations were most cracks were initiated and propagated, . Main cause of failure associated with stress assisted grain boundary oxidation, combined with cavitation. In addition, fractography confirmed brittle nature of the failure, possibly due to hydrogen embitterment.

Papers:

Metallurgical Aspects of a Blowdown Pipe Failure in a Petrochemical Plant, Eng. Fail. Analysis, 2019