2019, Kiani, M.

THESIS (BSc, 2017-2018): Spark plasma sintering of Stellite®-6 superalloy

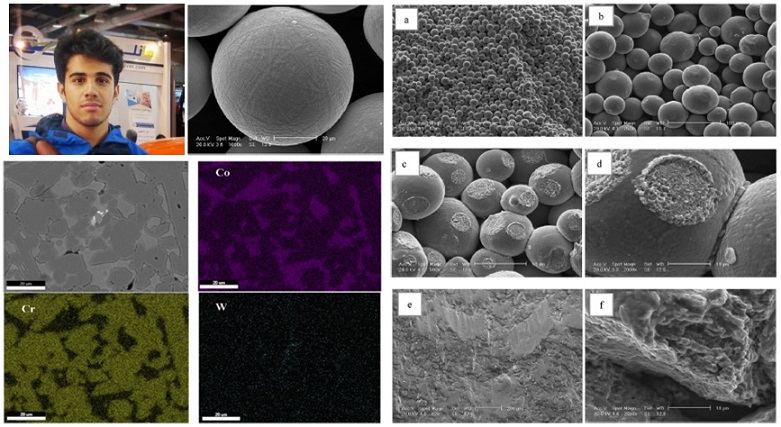

This research aimed at studying microstructure and mechanical properties of spark plasma sintered (SPSed) Stellite®-6 cobalt-based superalloy. SPS is a sintering technique, based on a relatively fast resistance heating using a pulsed current. Fast sintering process, associated with minimum grain growth, results in excellent mechanical properties. Samples were sintered at temperatures ranging from 950 to 1100 deg C. Microstructure of samples were studied using scanning electron microscope (SEM), energy-dispersive Xray spectroscope (EDS), X-Ray diffraction (XRD), and optical microscope. Hardness, impact test, as well as room and high temperature compression tests were used to evaluate the effects of sintering temperature and duration on the mechanical properties of SPSed samples. Results show that optimum mechanical properties can be obtained after sintering at 1050 deg C for 10 min. The correlation between sintering parameters, microstructure, and mechanical properties are discussed.

Papers:

Spark plasma sintering of Stellite®-6 superalloy, J. Alloys and Compounds, 2019